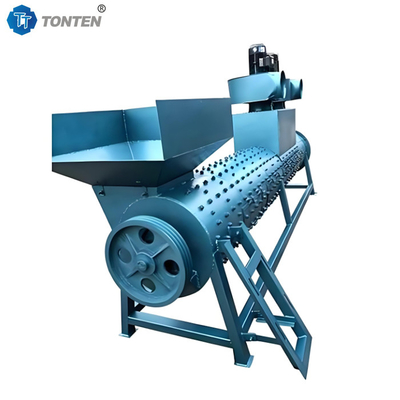

خط إعادة تدوير كسارة البلاستيك ذو الكفاءة العالية والتحكم الذكي

تفاصيل المنتج:

| مكان المنشأ: | الصين |

| اسم العلامة التجارية: | TONTEN |

| رقم الموديل: | TT-SLP01 |

شروط الدفع والشحن:

| الحد الأدنى لكمية: | 1 مجموعة |

|---|---|

| الأسعار: | قابل للتفاوض |

| تفاصيل التغليف: | حاوية |

| وقت التسليم: | 10-15 يوم عمل |

| شروط الدفع: | T/T |

| القدرة على العرض: | 20 وحدة / شهر |

|

معلومات تفصيلية |

|||

| التطبيق: | إعادة التدوير | العملية: | سهل |

|---|---|---|---|

| الحرارة: | خاضع للسيطرة | المعدات الداعمة: | محرك، خفض، عمود شفرة، شفرة |

| تحميل المواد: | بلاستيك PVC | المنتج النهائي: | حبيبات بلاستيكية |

| التأثير: | جيد | نقاط بيع - مراكز البيع: | سهل التشغيل |

| إبراز: | خط إعادة تدوير كسارة البلاستيك منخفض الاستهلاك,خط إعادة التدوير للتحطيم البلاستيكي ذو التحكم الذكي,خط إعادة تدوير كسر البلاستيك عالي الكفاءة,Smart Control Plastic Crushing Recycling Line,High Efficiency Plastic Crushing Recycling Line |

||

منتوج وصف

خط إعادة تدوير كسارة البلاستيك ذو الكفاءة العالية والتحكم الذكي

مقدمة المنتج

خط إنتاج كسارة وإعادة تدوير البلاستيك هو معدات آلية تتضمن فرز، سحق، تنظيف، تجفيف وتحقيق الحبيبات. نظام السحق يتبنى شفرات سبيكة مقاومة للاستخدام،والتي يمكن أن تتعامل مع مجموعة متنوعة من النفايات البلاستيكية الحرارية؛ نظام التنظيف والتجفيف يحقق نظافة عالية من خلال تنظيف الطبول، وتنظيف الاحتكاك وتجفيف الهواء الساخن.يتم تجهيز نظام التحليل بالجهاز المحدد لتحديد درجة الحرارة لإنتاج حبيبات متكررة موحدة؛ نظام التحكم الكهربائي يدعم بدء وقف واحد المفتاح وإشعار خطأ. خط الإنتاج مناسب لإعادة تدوير PET، PE، PP وغيرها من النفايات البلاستيكية،والقدرة يمكن تخصيصها وفقًا لخصائص المواد الخام وظروف الموقع، ويتم استخدامه على نطاق واسع في مجالات إنتاج البلاستيك المعاد تدويره، ومعالجة التعديل والحدائق الصناعية الاقتصاد إعادة التدوير.

مزايا المنتج

ضمان جودة دائم وموثوق به

المكونات الأساسية مصنوعة من المواد عالية الجودة المقاومة للاستعمال، مثل شفرات السحق المصنوعة من سبيكة عالية القوة،ويتم تصميم الهيكل لتكون متينة ويمكن أن تتحمل عملية عالية الحمل على المدى الطويلهيكل المعدات الوحيدة يسهل الصيانة اليومية واستبدال الأجزاء، ويقلل من وقت التوقف، ويضمن التشغيل المستقر لخط الإنتاج، ويقلل من تكاليف الصيانة ومخاوف المستخدمين.

الاستدامة المتوافقة مع البيئة

يتم تجهيز أجهزة احترافية لمعالجة الغبار والمياه العادمة في عملية السحق والتنظيف ، مما يقلل بشكل فعال من انبعاثات الغبار وتلوث مياه الصرف الصحي ،بما يتماشى مع المعايير البيئية المحلية والدوليةتقنية إعادة تدوير المياه وتصميمات توفير الطاقة تقلل من استهلاك الطاقة والمواردمساعدة المستخدمين على بناء نموذج إنتاج أخضر يلبي احتياجات الاقتصاد الدوري العالمي وسياسات حماية البيئة.

إنتاج مستقر ذو قيمة مضافة عالية

من خلال التحكم الدقيق في درجة الحرارة والتحكم في العملية، ينتج نظام التحليل الكريّة الحبيبات البلاستيكية المعاد تدويرها بحجم الجسيمات المتساوي ومحتوى الشوائب المنخفض،والذي يمكن استخدامه بشكل مباشر لاستبدال مواد جديدة في صب الحقن، تنفير الأفلام وغيرها من سيناريوهات المعالجة، مما يساعد المستخدم على تحقيق استخدام عالية القيمة المضافة من نفايات البلاستيك،وتعزيز القيمة المضافة للمنتج وتنافسيته في السوق.

مبدأ العمل

يجب وضع المعدات في وضعية مُهبلة، وتزيين المحامل بانتظام وتفقد العناصر اللاصقة، وتدوير الدوار يدويًا للتأكد من عدم وجود أي تشوهات قبل البدء.تجنب عملية الإفراط في الحمل· الحفاظ على تغذية المواد بشكل متساو أثناء العمل، وإيقاف الجهاز على الفور عند اكتشاف أي اهتزاز أو ضوضاء غير طبيعية أو درجة حرارة غير طبيعية.تحقق من حدة القطع ومرونة الحزام بشكل منتظم، وتعديل الفجوة المناسبة عند استبدال القطع؛ قطع إمدادات الطاقة أثناء الصيانة لضمان التشغيل الآمن.

قائمة المعايير

| القدرة الإنتاجية الفردية | 1000-1500 كيلوغرام/ساعة | درجة السحق | كسارة متوسطة | الرفاهية المُحطمة | سحق متوسط |

| القوة | 3700 واط | حجم جسيمات التغذية | 900 | تصنيف النجوم المطبق | خمسة |

| محتوى الرطوبة في المواد | 20% | صلابة المادة | 30 | المبدأ | كسارة البلاستيك |

| الوزن | 1990 كجم | السرعة | 18 دورة في الدقيقة | مستوردة أم لا | لا.. |

| فترة الضمان | الضمان لمدة سنة واحدة | قدرة الإنتاج | 1000-1500 كيلوغرام/ساعة | تشغيل الكهرباء | 380 فولت |

![]()