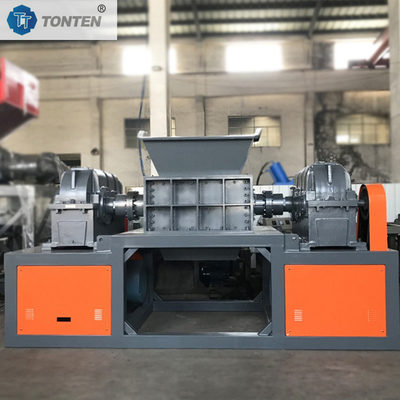

آلة تمزيق الأكياس المنسوجة ذات العمود المزدوج لتمزيق القماش القديم والخشب

تفاصيل المنتج:

| مكان المنشأ: | الصين |

| اسم العلامة التجارية: | TONTEN |

| رقم الموديل: | تي تي-S1000 |

شروط الدفع والشحن:

| الحد الأدنى لكمية: | 1 مجموعة |

|---|---|

| الأسعار: | قابل للتفاوض |

| تفاصيل التغليف: | النماذج الصغيرة معبأة في صناديق خشبية، النماذج الكبيرة تحمل في حاويات |

| وقت التسليم: | 7-10 أيام العمل |

| شروط الدفع: | ر/ر |

| القدرة على العرض: | 20 مجموعة في الشهر |

|

معلومات تفصيلية |

|||

| قوة المحرك: | 30 كيلو وات | عدد شفرات التقطيع: | 20 قطعة |

|---|---|---|---|

| حجم منفذ التغذية: | 1000x800 ملم | مادة الجسم: | الصلب الكربوني |

| وضع القيادة: | محرك مزدوج محرك | المواد المعمول بها: | حقيبة منسوجة القماش القديم الخشب |

| أبعاد: | 3000 × 2000 × 2000 مم | اسم النموذج: | تمزيق شافت مزدوج |

| إبراز: | آلة تمزيق الأكياس المنسوجة,آلة تمزيق القماش ذات العمود المزدوج,آلة تكسير وتقطيع الخشب,double shaft cloth shredder,wood shredding crusher machine |

||

منتوج وصف

حقيبة منسوجة مزدوجة عمود محطم محطم القماش القديم آلة الخشب

الخصائص الهيكلية

تصميم العمود المزدوج: باستخدام عمودين متوازين متناوبين ، يوفر الممزق ذو العمود المزدوج تكسيرًا أكثر توحيدًا ، مما يقلل من انسداد المواد وتوقفها.

نظام الشفرة: مجهزة بشفرات شرير متعددة ، عادة ما تكون مصنوعة من الصلب ذو السبائك العالية لتحقيق قوة عالية ومقاومة للارتداء.الترتيب العقلاني للشفرات يضمن تقطيع فعال لمجموعة واسعة من المواد.

هيكل الجسم: عادة ما يتم بناء الجسم من فولاذ الكربون الثقيل ، مما يضمن الاستقرار والمتانة تحت الأحمال العالية.

نظام الطاقة: يتم تجهيز أجهزة التقطيع ذات العمودين بمحركين ، مما يوفر طاقة قوية ويضمن التقطيع الفعال والسريع.

مدخل التغذية: مدخل التغذية العريض ، الذي يبلغ عادة 1000 × 800 مم ، يسهل إدخال المواد ويستوعب مجموعة واسعة من المواد.

نظام التحكم: يتم تجهيز الممزقات ذات العمودين بنظام تحكم تلقائي PLC ، مما يتيح التشغيل الآلي وتعزيز راحة المستخدم وسلامته.

نظام التبريد: يستخدم تبريد الهواء أو الماء لمنع الأضرار الناجمة عن ارتفاع درجة الحرارة أثناء التشغيل لفترة طويلة.

السلامة: العديد من عناصر السلامة تضمن سلامة المشغل.

سير العمل:

إعداد المواد: وضع المواد التي سيتم تقطيعها في منفذ التغذية، وضمان أن حجم المواد مناسب للآلة.

تشغيل الآلة: تشغيل المحرك، تبدأ الآلة في العمل، وبدأ العمودين في الدوران.

عملية التقطيع: تدخل المادة إلى غرفة التقطيع في محطم العمود المزدوج ، حيث تمزق وشفرات العمود المزدوج المادة وتقطيعها ، وتكسرها تدريجياً إلى قطع أصغر.

تصريف المواد: يتم تصريف المواد الممزقة من خلال منفذ التفريغ ، عادةً لمزيد من المعالجة على شريط نقل أو معدات أخرى.

مراقبة وتعديل: يمكن للمشغل مراقبة حالة الجهاز من خلال لوحة التحكم وإجراء التعديلات والصيانة حسب الضرورة.

التنظيف والصيانة: تنظيف وتصليح الممزقة ذات العمودين بانتظام لضمان التشغيل المستقر على المدى الطويل.

المواصفات الخاصة بمحطم العمود المزدوج:

|

نوع الطراز |

مقاس الأبعاد ((ملم) |

حجم العلف ((ملم) |

شفرات ((ملم) |

قوة المحرك ((kw) |

الوزن ((كجم) |

|

TT-S600 |

2300x1500x1620 |

600×460 |

200 |

11 × 2 |

1580 |

|

TT-S800 |

2820×1600×2050 |

800×720 |

260 |

15 × 2 |

3500 |

|

TT-S1000 |

3300 × 1900 × 2200 |

1000 × 800 |

300 |

22 × 2 |

5000 |

|

TT-S1200 |

3500×2000×2500 |

1200×980 |

320 |

30 × 2 |

6200 |

|

TT-S1500 |

4100 × 2260 × 2800 |

1500 × 1000 |

550 |

55 × 2 |

7000 |

|

TT-S1600 |

5800 × 2400 × 3300 |

1800×1206 |

560 |

75 × 2 |

7500 |

|

TT-S1800 |

6100 × 2700 × 3500 |

2000×1490 |

600 |

90 × 2 |

8900 |

ورشة عمل آلة التقطيع:

![]()